NEWS

Leyard Leads MIP G2 Technology Innovation, Pioneering in a New Era of Micro LED Display

2025.03.17

Recently, the 6th Global Mini/Micro LED Display Technology Week in 2025 was held in Xiamen. As an industry leader, Leyard Group demonstrated its important technological breakthroughs and progress in MIP G2 research and development to the world. Pan Tong, General Manager of Leadstar Microelectronics under Leyard Group, was invited to deliver a keynote speech entitled "MIP Mass Production Path Breakthrough and Productization Application", and systematically disclosed the strategic panorama of MIP for the first time, which attracted great attention from the industry.

As the executive vice president unit of China Video Industry Association Mini/Micro LED Display Industry Branch (CMMA), Leyard Group has participated in compiling the White Paper on Mini/Micro LED Display Industry and a number of industry specifications for several consecutive years.During this technology week, representatives from the group engaged in discussions with over 200 core enterprises and experts from the upstream and downstream of the industry chain, including Tianma, TCL, and Huawei, on how LED display technology can empower various industries.

Leyard's MIP product line layout is strategically planned based on Micro LED dies, encompassing both RGB single-pixel packaging and N-in-1 multi-pixel packaging devices. The product line adheres to the idea of continuous die miniaturization, driving PM → AM transformation, and continues to promote innovation and change.

Technical breakthrough: Define a new benchmark for MIP G2

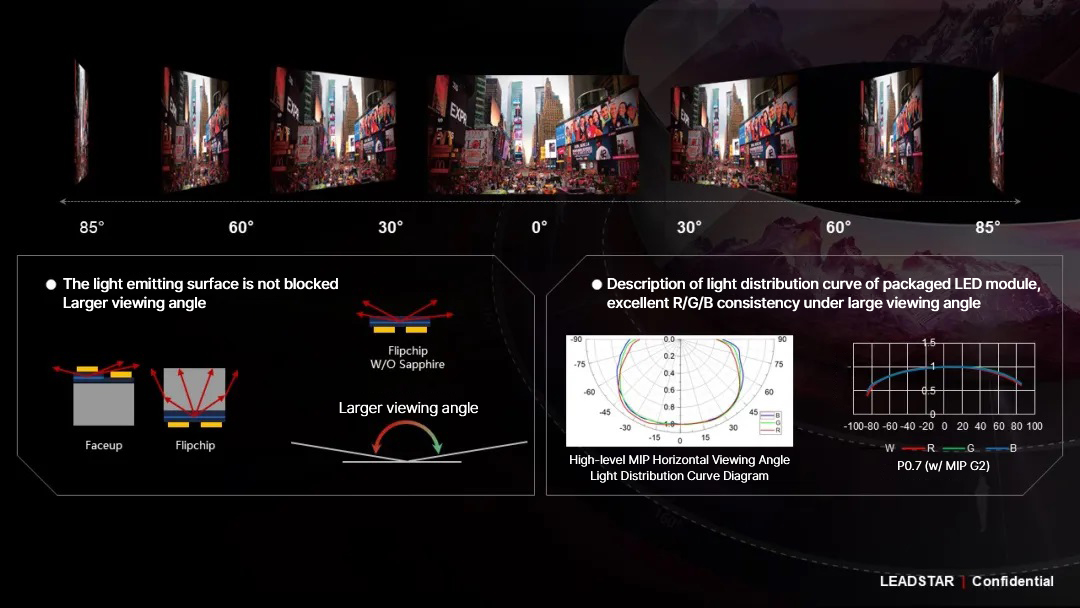

The MIP G2 (MicroLED in Package) products utilize flip-chip technology with a substrate free design and incorporate Micro LED dies smaller than 50μm. These products feature a black area ratio exceeding 99%, excellent consistency in color temperature and chromaticity viewing angles, and support 0303/0404 package sizes. Designed with a common cathode configuration, they offer enhanced energy efficiency and lower power consumption.

The display effect is remarkable. The half power angle of the substrate free RGB LED die is consistent, which means that the LED screen can still maintain the consistency of color temperature and chroma at a large angle of more than 170 °, which perfectly solves the problem of color deviation.

Capacity upgrading: building large-scale mass production barriers

In November 2024, Leyard's first-phase, fully self-developed MIP Generation 2 production line (Micro LED packaging technology) officially commenced operations at the Wuxi Leadstar factory. This development is set to significantly drive the demand for high-definition displays below 1mm, delivering Micro LED products with higher cost-performance ratios and superior display quality to the market. The initial phase is expected to achieve a production capacity of 1200KK per month, with the second phase expanding capacity to 2400KK per month.

Cost Innovation: Unlocking Market Penetration

The size of Micro LED flip-chip die continues to shrink, leading to a corresponding decline in the cost of core raw material dies. Additionally, compared to COB products, MIP products have lower requirements for PCB substrate production, resulting in improved yield rates and a significant reduction in manufacturing costs.

High-Efficiency Automated Production: The MIP bead automated production line, which reaches dust-free cleanliness level 1000 , enables automation and intelligentization of the production process. Leveraging self-developed mass transfer and bonding technology, it achieves a transfer efficiency of 6000kUPH, which is 150 times that of conventional die bonders.

Yield and Efficiency Exceed Industry Averages: Currently, Leadstar Microelectronics possesses key process equipment for mass transfer, mass bonding, mass inspection, and mass slicing. The yield and efficiency at critical stages of the overall production process surpass industry averages, with the yield of MIP G2 products exceeding 95%.

The technological inflection point has arrived, with the mass production of MIP technology set to become the core driving force. Leyard Group, by building a comprehensive innovation chain, is vigorously accelerating the deep application and expansion of MIP technology across multiple fields, injecting robust momentum into the transformation and upgrading of the global display industry.

Share To

Related Media Reports

2025.09.28

Statement on the Adjustment of Leyard Group’s Regional Brand Agency Policy

2025.09.28

30 Years of Pioneering and Innovation: Leyard Sets Sail on the 'Display + Cultural Tourism + AI' Journey with Breakthrough Products

2025.08.25

-1_1661389830.jpg)